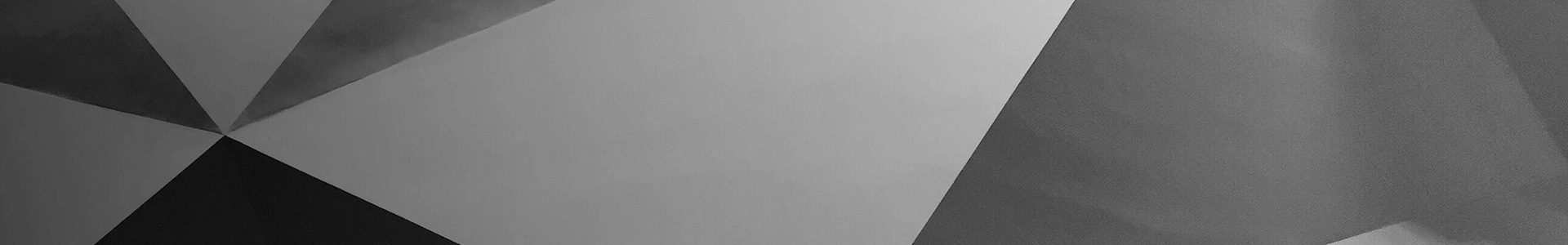

Custom Metal Shrapnel Hardware Shrapnel Battery Shrapnel Automotive Brake Shrapnel Hardware Stamping Parts

Basic Info.

| Model NO. | According to customer requirements |

| Surface Processing | Electroplating |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Customized | Customized |

| Transport Package | Carton or Wooden Pallet According to Customer′s Re |

| Specification | 20mm * 20mm * 15mm |

| Trademark | Can be customized |

| Origin | China′s Hebei Province |

| HS Code | 7326199000 |

| Production Capacity | 1000000 Every Day |

Product Description

Basic Info.

Basic Product Information

| model | Custom BYTP - 001 | mould | Automatic continuous mode |

| industry | Metal stamping molding | Transport packaging | As specified by the customer |

| use | Brake pads for cars The battery mechanical | experience | 20 years manufacturing experience |

| The sample | Provided free of charge | material | Can choose copper stainless steel manganese steel and so on |

| The trademark | OEM | packaging | According to customer requirements |

| process | Stamping forming | transport | Land transport Marine aviation |

| service | OEM / ODM | Production capacity | The daily output is 5 million |

| The tolerance | 0.05mm | origin | China's hebei province |

Product features

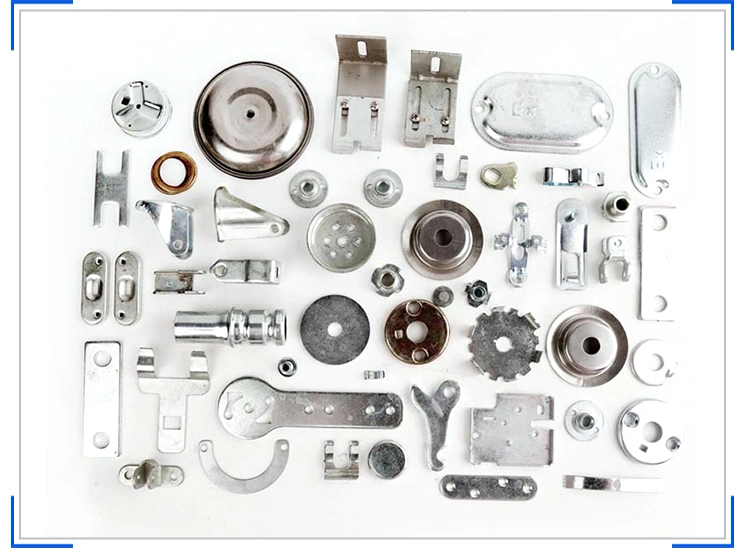

| material | Stainless steel 65 manganese steel Brass bronze aluminum alloy APCC zinc white copper |

| Processing method | Stamping welding sheet metal assembly drawing CNC processing |

| Surface treatment | Electroplating, anodizing, sandblasting, powder spraying, liquid spray painting, electropolishing, etc |

| Material standard: | ISO,DIN,ASTM,UNS,AISI,JIS,BS,NF |

| Custom service | Professional customization of all kinds of metal materials non-standard products |

| Product delivery time | 25 to 30 days |

| Major Export Markets | Europe America Middle East Asia Africa |

| Range of application | Auto parts aerospace avionics medical appliances lighting building machinery electronics shielding and other industries |

How we work:

1. Send your drawings or samples to us, we will be fine

A quasi-quick quote;

2. Timely send samples and send them to you by express;

3. Mass production after your complete confirmation to ensure customer satisfaction and rest assured.

4. We are the manufacturer's own production and sales, can protect customers

Product stability and delivery accuracy

Metal parts stamping

The application of metal accessories stamping covers every corner of modern life, according to the use can be roughly divided into:

1. Daily and household metal stamping parts: such as POTS and pans, sinks, kettles and other daily necessities, and such as washing machine, air conditioner, refrigerator, rice cooker and other household appliances;

2. Industrial hardware stamping parts: equipment case shell, vehicle sheet metal and construction machinery stamping parts;

3, tight device type stamping hardware: instrumentation devices, connectors, etc.;

4. Special stamping hardware for aerospace ships. 5. Electrophoretic paint process has corrosion resistance and oxidation resistance, the surface of the paint and the product has super adhesion ability, and beautiful

Hardware stamping parts characteristics and applications

Metal stamping parts is a forming process method of obtaining the desired shape and size of the workpiece (metal stamping parts) by applying external force on the plate, strip, pipe and profile by press and die, so as to produce plastic deformation or separation. Stamping and forging belong to plastic machining (or pressure machining), collectively known as forging. The blank for stamping is mainly hot and cold rolled steel sheet and strip. Stamping is mainly classified by process, which can be divided into two categories: separation process and forming process.

Metal stamping parts are mainly metal or non-metal sheet material, with the help of the press pressure, through the stamping mold stamping forming, it has the following characteristics:

(1) Metal stamping parts is in the material consumption is not large under the premise, by stamping manufactured, its parts light weight, good stiffness, and after plastic deformation, metal internal structure has been improved, so that metal stamping parts strength has been improved.

The metal stamping parts have high dimensional accuracy, uniform and consistent with the mold size, and have good interchangeability. No further machining is required to meet the general assembly and use requirements.

(3) Hardware stamping parts in the stamping process, because the surface of the material is not damaged, it has a better surface quality, appearance smooth and beautiful, which provides convenient conditions for surface painting, electroplating, polishing and other surface treatment.

We adhering to the integrity-based, customer first business philosophy, with senior industry elite and advanced equipment to provide powerful guarantee for product quality, with strict production management and the rigorous work attitude to ensure efficient production and service, to provide perfect after-sale to advanced response mechanism of innovative consciousness and timely service, with new and old customers to create a more brilliant future.

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer.

Q: What quotation do you need to provide?

A: Please send us drawings or samples of your products. The following details shall be included, A. Materials

(B) Surface treatment C) tolerance D) Quantity E) Terms of delivery (Please note that these are crucial to our offer.

Thank you for your understanding and support.

Q: How does the payment process work?

A: The terms of payment are flexible to us and can be determined according to specific circumstances.

Usually we recommend 30%-50% TT deposit and the balance will be paid before delivery.

Q: How do I know about production?

A: We will reconfirm your requirements and send you samples before mass production.

We will keep you informed of any developments during mass production. In addition, we will carry out 100% quality check before shipment.

(We will provide you with pictures, videos and measurement reports if you need them.)

Q: How do I know delivery status?

A: We will notify you as soon as we obtain the tracking number from the shipping agent.

In addition, we will keep you updated with the latest shipping information.

A: When our metal parts are suitable for your products, we will follow up and wait for your feedback.

Q: What about after sales?

Any problem with our metal parts, our experienced engineers are ready to help.

Q: What finishes do you have?

A: Galvanized, nickel plated, tin plated, brass plated, silver plated, gold plated, anodized, etc.

Q: Can I get a sample?

A: Yes, the sample order can be used for quality inspection and market testing. It will be freight collected. If it is a simple sample, we will not charge the fee; In case of OEM/ODM samples, we will charge the sample fee.

Q: What is the minimum order quantity?

A: The minimum order quantity when in stock is 100 pieces.

Q: What is the lead time?

A: Standard stamping is 3~7 days after payment. In case of OEM or mould manufacturing, we will confirm the delivery time with you.

Q: What are your payment terms?

A: The terms of payment are flexible to us and can be determined according to specific circumstances. Generally we recommend a 30%TT deposit and pay the balance before delivery

Q: Have you received OEM/ODM?

Answer: Yes. We have over 15 years of OEM experience

Welcome to our factory. Our goal is to be your most reliable supplier, please contact us